Printed Device

Thin, Light and Soft

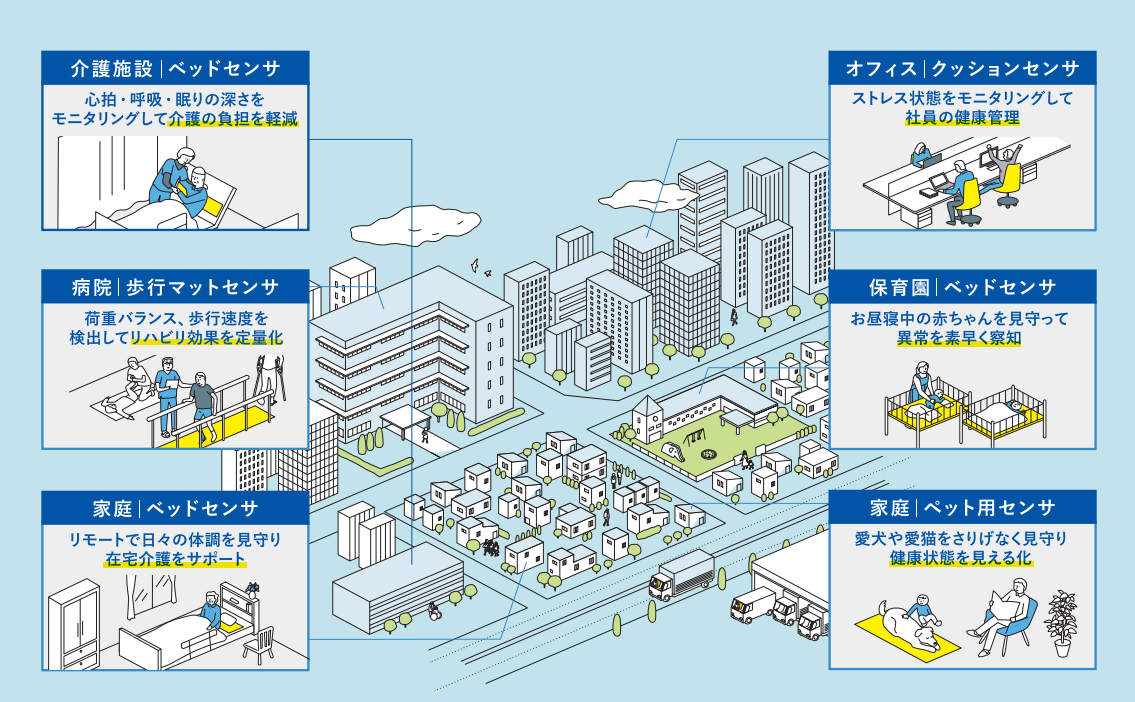

Film Sensor that can Design 3D Space

Future Ink productizes film sensors with the printed electronics technology that is used for electronic device production using printing processes.

This supports production with a large area and enables mass-production and cost-reduction

as well as free design of sensing space thanks to devices that are less than 0.5 mm, lightweight and flexible.

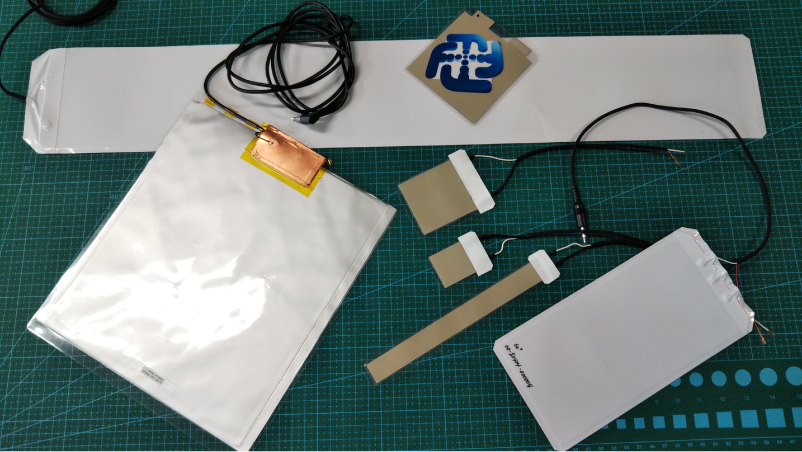

Piezoelectric Sheet Sensor

This pressure Sheet Sensor uses an organic piezoelectric material that generates voltage from vibrations or bending.

The sheets excel at high-sensitive signal measurement and also enable measuring very weak vital signs such as pulse waves and breathing without restraining body motion.

This can also be applied to bed sensors by using printing processes to increase the Sheet Sensor size.

Sensing the Human Life With Smart Organics